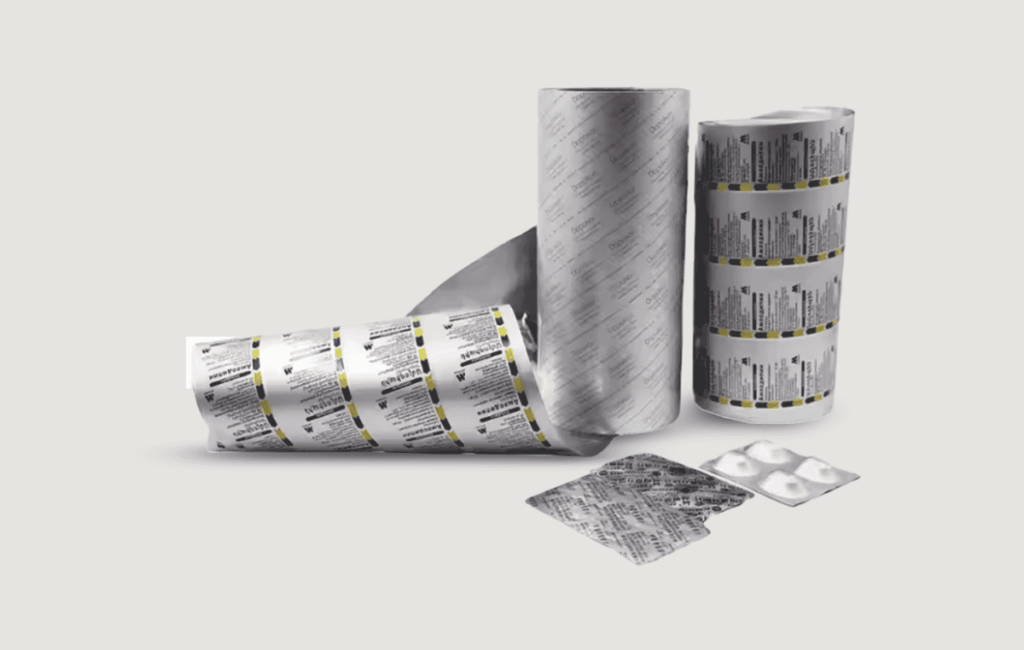

Premium Blister Foils for Pharmaceutical Packaging

High-Quality, Customizable Solutions for Tablets and Capsules

RAMA FOILS offers a wide range of blister foils designed for the secure and efficient packaging of pharmaceutical products like tablets and capsules. Our foils are manufactured using premium materials and advanced technology, ensuring durability, compliance with industry standards, and enhanced product safety. Whether you need standard or customized specifications, we deliver solutions tailored to your unique requirements.

Blister Foils

RAMA Foils offers a range of hard aluminum foils specially designed for blister packaging of pharmaceutical products such as tablets and capsules. We provide customized product specifications based on mutually agreed terms with our customers, ensuring every solution meets their unique requirements.

| STANDARD FOIL GAUGE OPTIONS | TOLERANCE ( +/- 8% ) |

|---|---|

| 0.020 mm | +/- 0.0016mm |

| 0.025 mm | +/- 0.002 mm |

| 0.030 mm | +/- 0.0024 mm |

HEAT SEAL COATING

Our foils feature a colourless vinyl resin coating, with an option for tinted resin, fully compliant with applicable government regulations for direct contact with medicines and pharmaceuticals. This coating is engineered for effective heat sealing to PVC or PVDC-coated PVC films.

COATING GSM OPTIONS

1. (a) 4-6 GSM with a tolerance of +/- 0.5 GSM

2. (b) 6-8 GSM with a tolerance of +/- 0.5 GSM Standard, if not specified, heat sealing coating GSM is 4 with a tolerance of +/- 0.5.

Seal Strength with PVC/PVDC: Minimum 8 N/25 mm

PRINTING & LACQUER COATING

Printing: Customized to customer-approved text, layout, and colour specifications.

Lacquer Coating (Non-Printed Foils): A clear lacquer is applied as a protective layer to enhance durability and printability.

All printing inks and lacquer coatings are formulated to withstand high temperatures, up to 180°C for a dwell time of 1 second.

CONFIGURATION

Printed Blister Foils: Available in reel form, tailored to customer requirements.

Unprinted Blister Foils: Offered in reel form or as jumbo rolls for broader applications.

| WINDING DIRECTION | Generally printed or clear lacquer side is out with heat Seal coating inside. | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CORE | Material options: (a) Plastic (b) Aluminium (c) Card Board Core ID: 76 mm +/- 0.5 mm The length of the core is equal to the width of the web. |

||||||||||||||||||||||||||||||

| SPLICES | Butt type made with 25 mm pressure sensitive tape. | ||||||||||||||||||||||||||||||

| REEL OUTER DIAMETER | 250 +/- 10 mm for slit material, 400 +/- 10 mm for Jumbos | ||||||||||||||||||||||||||||||

| REEL WANDER | Within +/- 1 mm | ||||||||||||||||||||||||||||||

| REEL/WEB WIDTH | Plain: 45mm to 800 mm with a tolerance of +/- 0.5 mm. Printed: 45mm to 600 mm with a tolerance of +/- 0.5 mm. |

||||||||||||||||||||||||||||||

| JOINTS PER REEL | Maximum 2. Average less than 1. | ||||||||||||||||||||||||||||||

| PIN HOLES | 0.025 and 0.03 mm foils are free from pin holes. In 0.02 mm foil, 40% of foil is free from pin holes, rest less than 10 PSM |

||||||||||||||||||||||||||||||

| IDENTIFICATION | Each reel shall be identified with a sticker pasted inside the core with Reel numbers. Specification, Net weight, Operator number & Date manufacture. |

||||||||||||||||||||||||||||||

| PACKING | Blister foils are packed in cardboard carton. Relevant Markings are provided on each outer package. | ||||||||||||||||||||||||||||||

| RECOMMENDED OPERATING CONDITIONS | Sealing temperature: 170 to 180 deg. C Sealing pressure: 2.8 to 5.6 kg/Sq.cm, 40 to 80 lbs/Sq. inch Dwell time: 0.25 to 0.5 sec. |

||||||||||||||||||||||||||||||

| COVERING AREA OF 1 Kg FINISHED MATERIAL (NOMINAL) | Gauge & Temper Foil 0.02 (hard) - 17.18 0.025 (hard) - 13.94 0.03 (hard) - 11.72 |

||||||||||||||||||||||||||||||

| TABLE SHOWING THICKNESS TOLERANCES OF FOIL: |

|

||||||||||||||||||||||||||||||

| TEST CERTIFICATES | Test certificates giving the actual observed values of different parameters will accompany the supplies. | ||||||||||||||||||||||||||||||

Why Choose RAMA FOILS?

Our blister foils are engineered to meet the highest standards of quality and performance. Here’s what makes them stand out:

Superior Protection

Provides excellent barrier properties against moisture, oxygen, and contaminants.

Customizable Options

Available in various gauges, coatings, and printing designs to suit your needs.

Industry Compliance

Meets all regulatory requirements for pharmaceutical packaging.

Durability

Designed to withstand high temperatures and ensure long-lasting product freshness.

Ready to Start Your Pharmaceutical Packaging?

Whether you need standard blister foils or customized solutions, RAMA FOILS is here to help. Contact us today to discuss your requirements, request a quote, or schedule a consultation.